Wood veneer

| Size |

4x8,4x7, 3x7, 4x6, 3x6 or as required |

|---|---|

|

Thickness |

0.1mm-1mm/0.15mm-3mm |

|

Grade |

A/B/C/D/D |

|

Grade features |

|

|

Grade A |

No discolor allowed, no splits allowed, no holes allowed |

|

Grade B |

Slight color tolerance, slight splits allowed, no holes allowed |

|

Grade C |

Medium discolor allowed, split allowed, no holes allowed |

|

Grade D |

Color tolerance, splits allowed, within 2 holes diameter below 1.5cm allowed |

|

Packing |

Standard export pallet packing |

|

Transport |

By break bulk or container |

|

Delivery time |

Within in 10-15 days after receiving deposit |

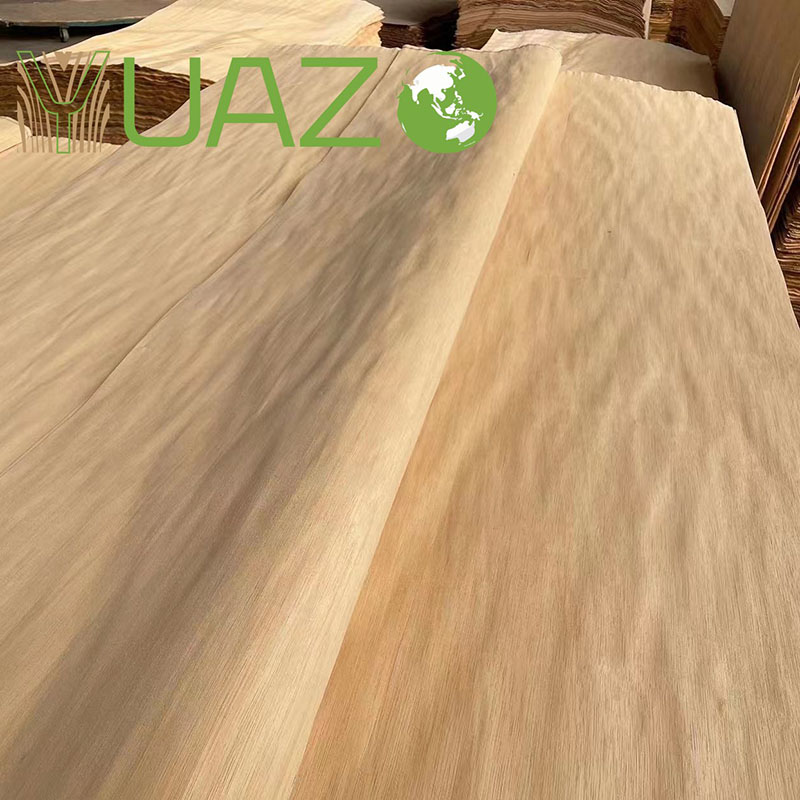

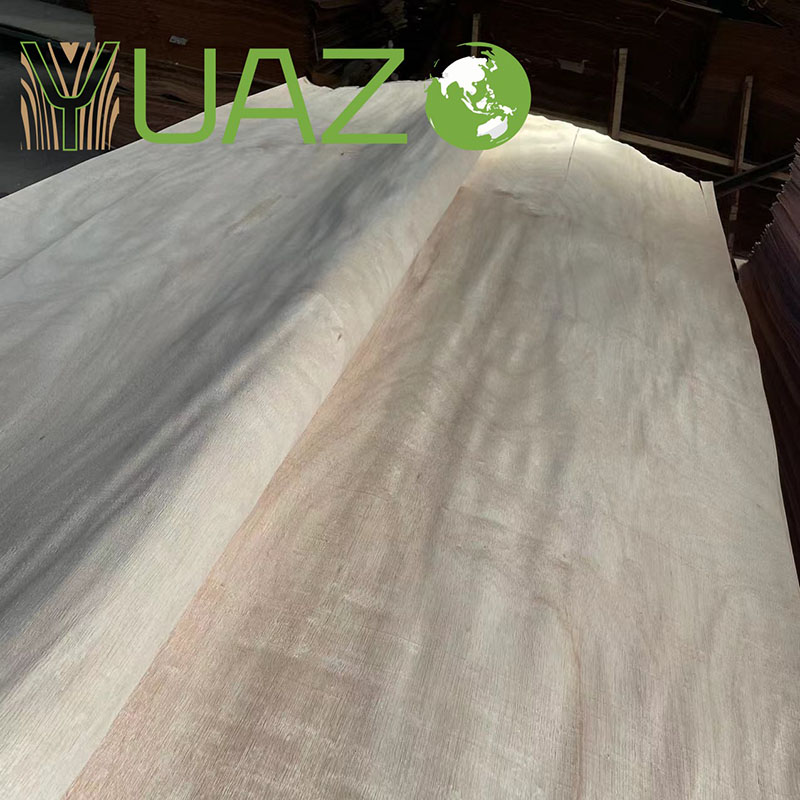

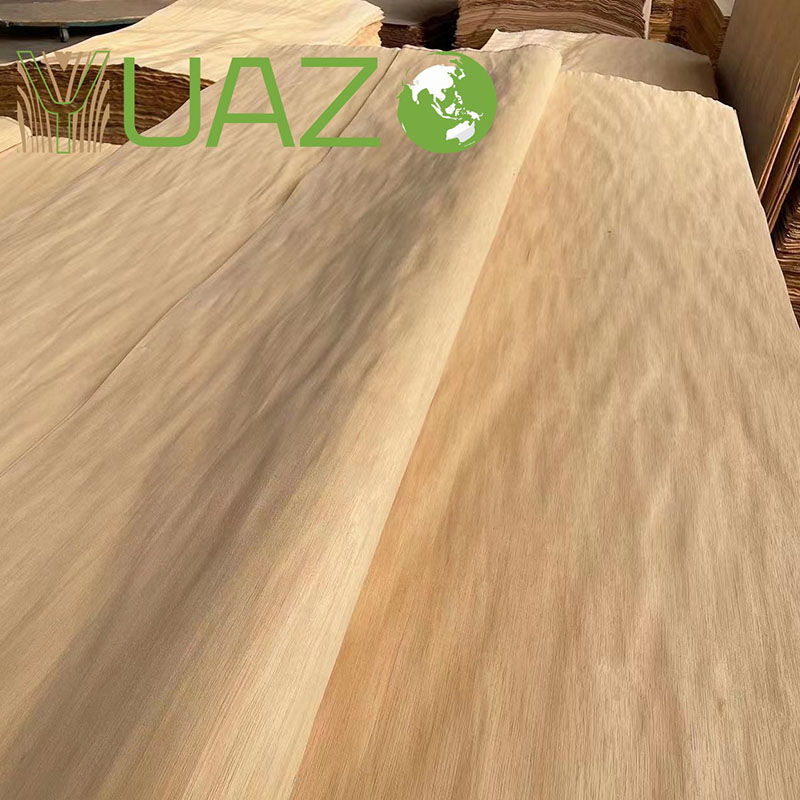

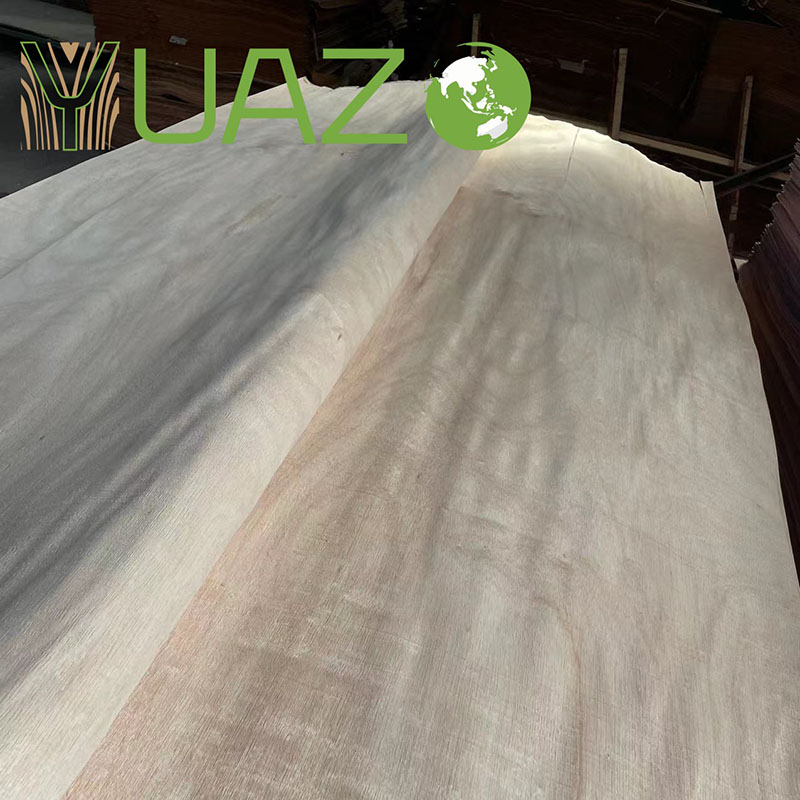

Performance and characteristics of natural wood veneer:

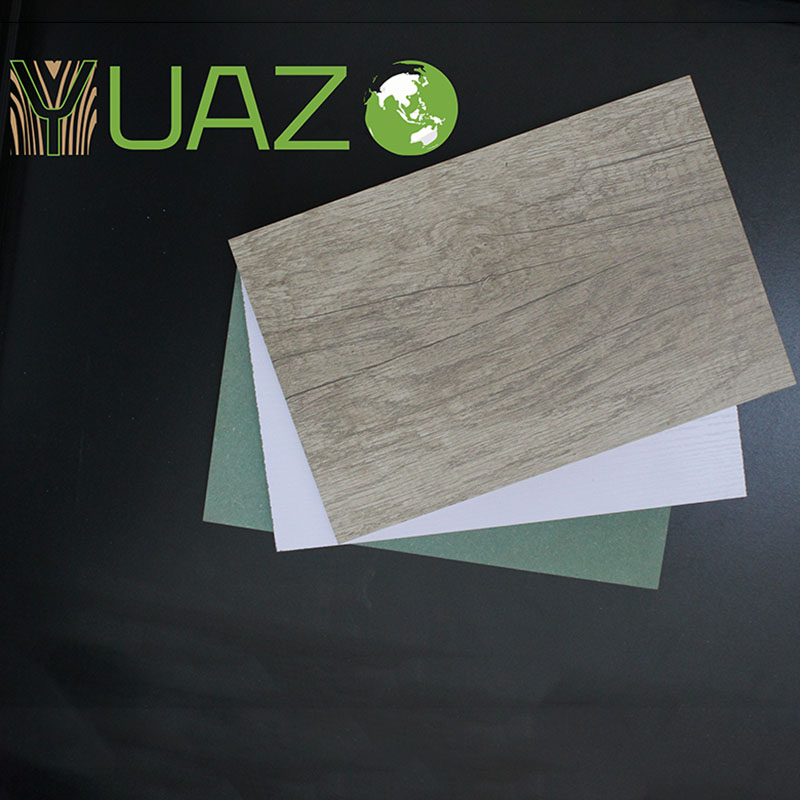

It has the natural and simple fragrance of wood, strong texture, and its special and irregular natural texture has superb and ingenious artistic charm, which can give you the original heartbeat of returning to nature and the artistic enjoyment of beauty. However, veneer is widely used: thin veneer is used in the production of veneer, paper skin and non-woven skin; thick veneer is used in furniture production, veneer parquet, and composite floor board veneer.