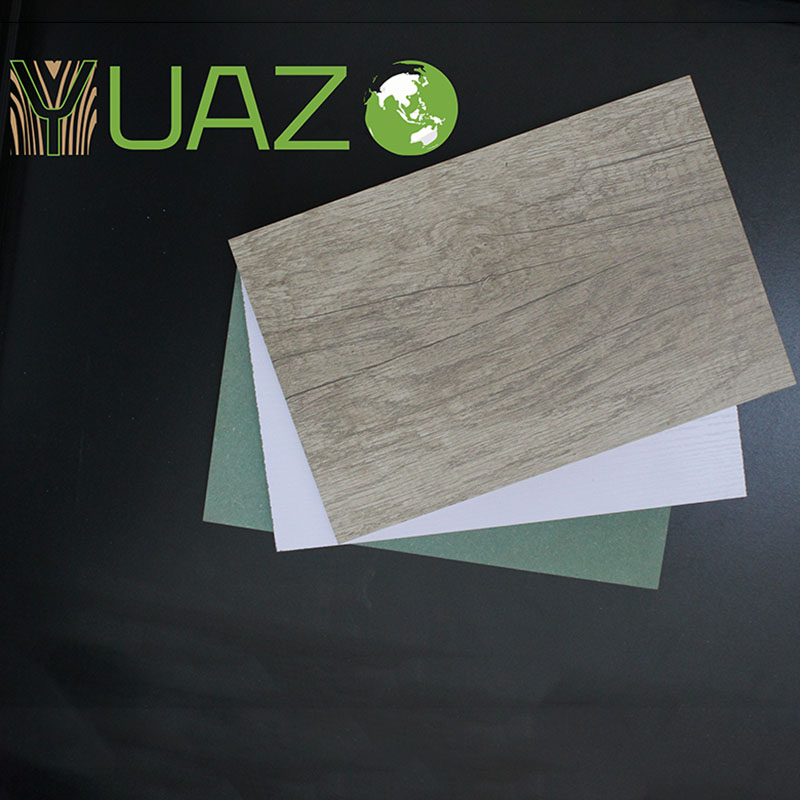

White oak

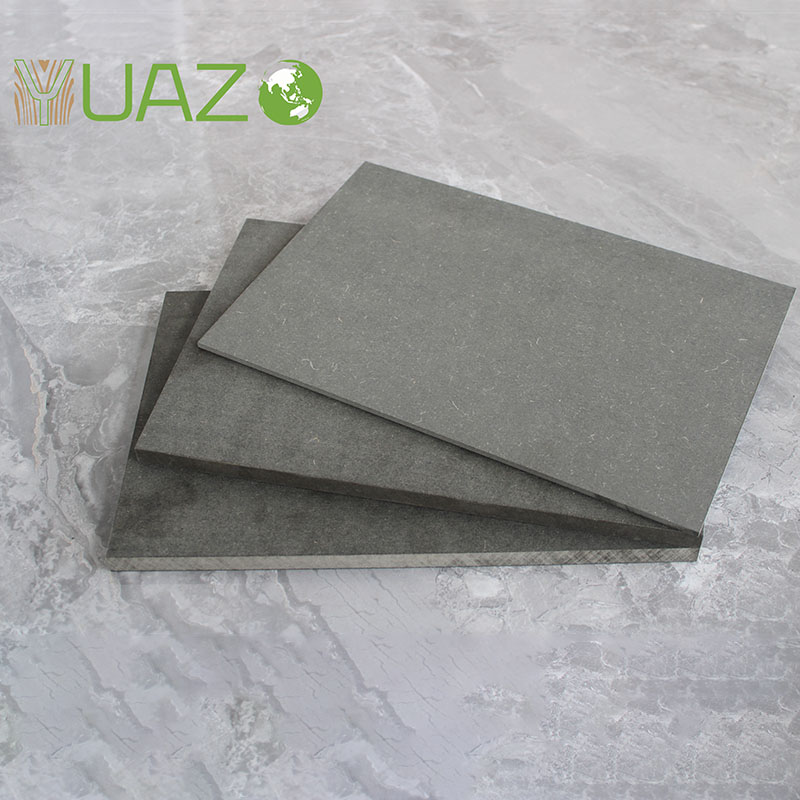

| Size |

4x8,4x7, 3x7, 4x6, 3x6 or as required |

|---|---|

|

Thickness |

0.1mm-1mm/0.15mm-3mm |

|

Grade |

A/B/C/D/D |

|

Grade features |

|

|

Grade A |

No discolor allowed, no splits allowed, no holes allowed |

|

Grade B |

Slight color tolerance, slight splits allowed, no holes allowed |

|

Grade C |

Medium discolor allowed, split allowed, no holes allowed |

|

Grade D |

Color tolerance, splits allowed, within 2 holes diameter below 1.5cm allowed |

|

Packing |

Standard export pallet packing |

|

Transport |

By break bulk or container |

|

Delivery time |

Within in 10-15 days after receiving deposit |

In the past ten years, my country's furniture manufacturing and decoration industries have widely used thin wood veneer technology. The following is some research on thin wood, for your reference only:

1. Classification of thin wood

Classification by thickness

Thickness greater than 0.5mm is called thick wood; otherwise, it is thin wood.

2. Classification by manufacturing method

It can be divided into planed thin wood; rotary cut thin wood; sawed thin wood; semi-circular rotary cut thin wood. Usually, the planing method is used to make more.

3. Classification by form

It can be divided into natural veneer; dyed veneer; combined veneer (technical veneer); spliced veneer; rolled veneer (non-woven veneer)。