The main uses of density board

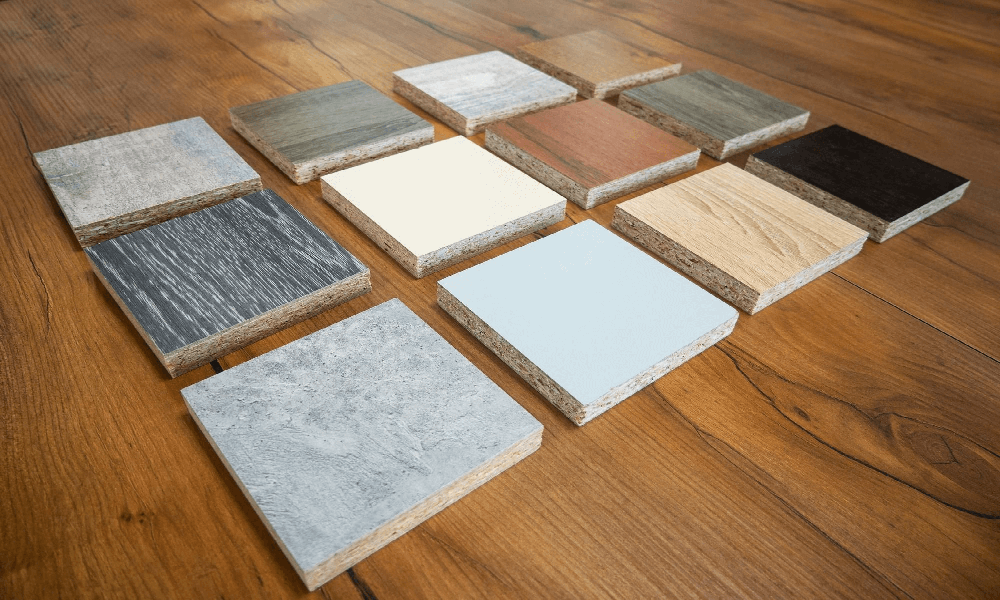

Density board, also known as fiberboard, is an artificial board made of wood fiber or other plant fibers as raw materials and applied with urea-formaldehyde resin or other applicable adhesives. According to their different densities, they are divided into high-density boards, medium-density boards, and low-density boards. MDF is easy to paint. Various oily and gelatinous paints can be painted on density board to make it beautiful and durable. The density board itself is also a beautiful decorative board. The photocatalyst can be applied to the structural parts that are decorated or need to be insulated. It can also be glued with a variety of beautiful tape films and plastic veneers, veneers or light metal sheets. Stick it on the surface of the density board. So what is the main role of density board? Next, I will answer them one by one. Depending on the type of density board, its functions are also different.

What are the uses of different density boards?

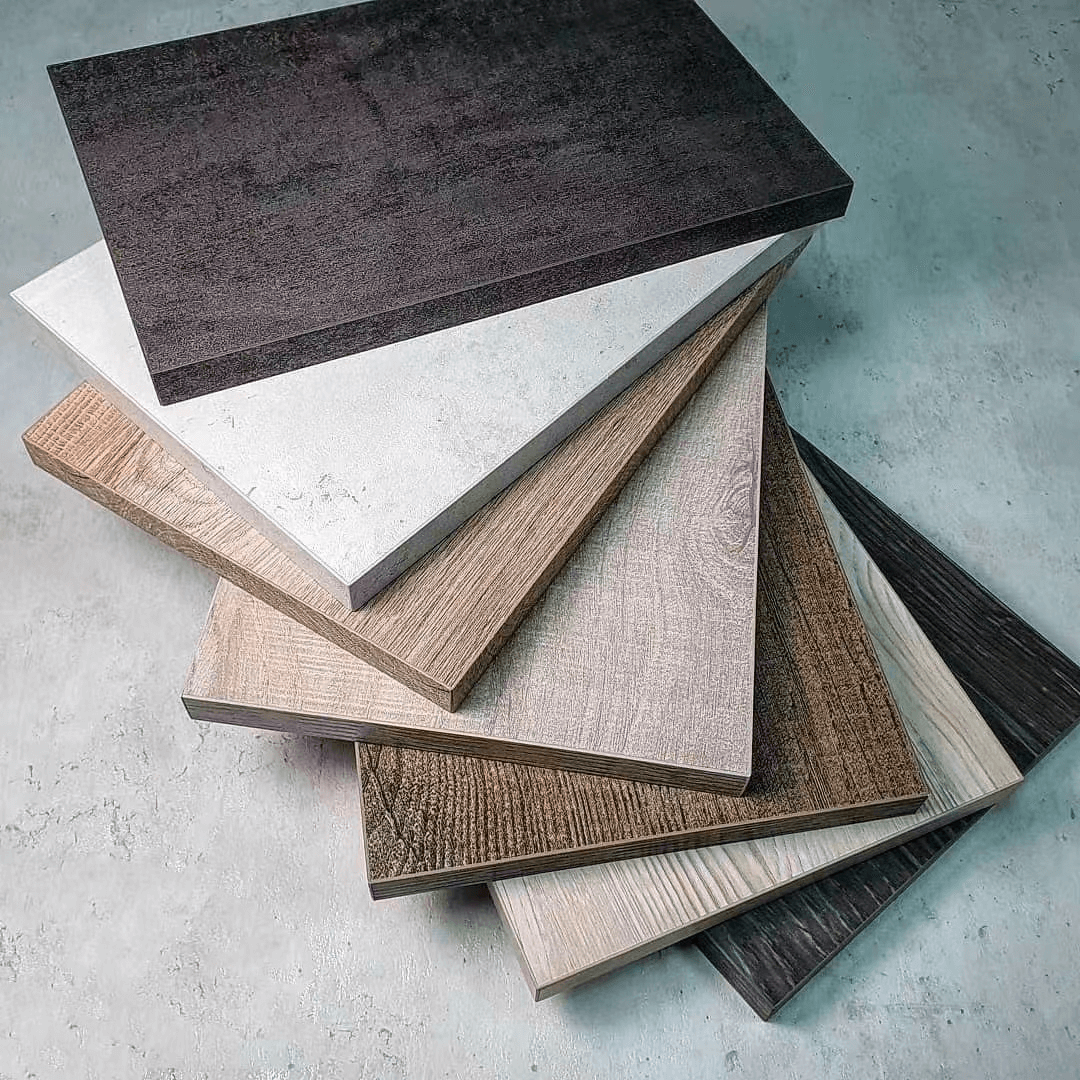

1. Standard board: Standard board is a material with a smooth surface on one side and a textured finish on the other. It is used for cabinets, drawer bottoms and wall panels that are hidden parts.

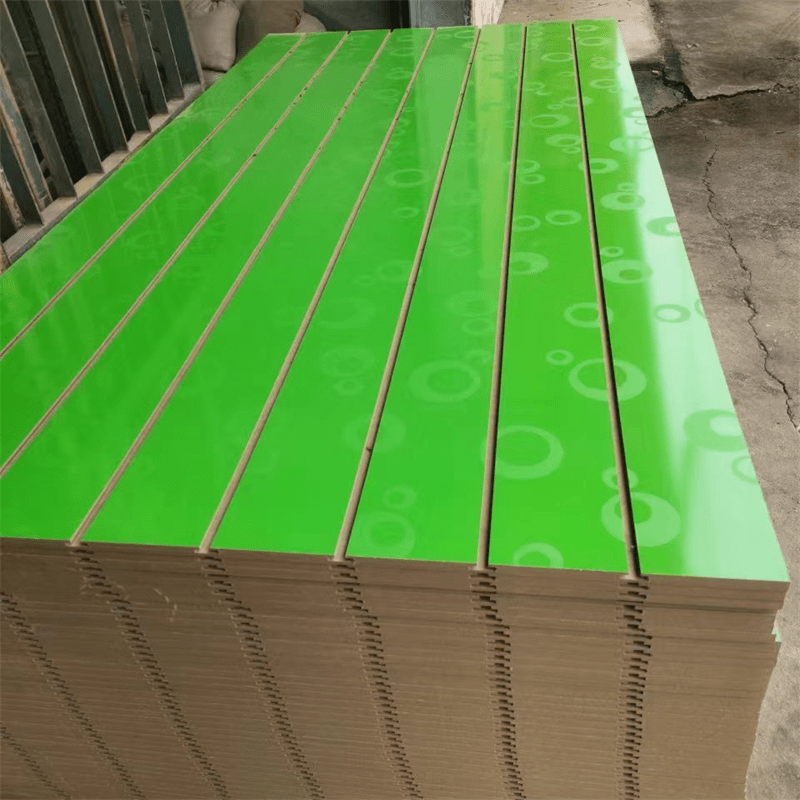

2. Glazed panel: The surface of glazed panel is painted and often affixed with facing tiles or stamped into facing tiles or noodle board patterns. It is used for wall panels or wall panels around bathtubs.

3. Plastic veneer: Plastic veneer is used for sliding doors, which is decorative and easy to clean. However, it should not be used on areas where the surface is worn.

4. Hard fiberboard (also known as high-density fiberboard): Hard fiberboard is an excellent substitute for wood. It can be used for indoor floor decoration, indoor wall decoration, and decoration. It can be used to make hard fiberboard indoor partition walls. The bread box method is used to achieve the purpose of sound insulation. After punching and drilling, the hard fiber board can also be made into a sound-absorbing board and used in building ceiling projects.

5. Ordinary medium-density fiberboard and ordinary medium-density fiberboard can be used in all walks of life, and their main uses are as follows.

Furniture industry: Various panel-type modular furniture and table frame furniture are used to produce various furniture components, such as panels, side panels, back panels, office screens, etc.

Construction and decoration industry: Typical uses include: laminate flooring (ordinary or moisture-proof medium density fiberboard), wall panels, ceilings, doors, door skins and door openings, various indoor partitions, building accessories such as stairs, skirtings, Mirror frames, various decorative panels and decorative lines. Vehicle and ship manufacturing: MDF can be used for interior decoration of ships, trains, and cars after veneer. It can replace plywood. However, when the environment is humid and fire protection requirements are high, it can be veneered or use special types of MDF. solve.

Audio equipment: Medium-density fiberboard is a homogeneous multi-layer material with good acoustic performance. It is very suitable for speakers, TV casings, and musical instruments.

Other applications: MDF can also be used in many places, such as: luggage frames, packaging boxes, ceiling fan blades, shoe heels, toy puzzle blocks, clock casings, billboards-outdoor signs, display stands, shallow bottom trays, ping pong tables , sculptures, models, etc.

6. Special medium-density fiberboard: Moisture-proof medium-density fiberboard is currently used in shoe heel materials and floor materials, with thickness specifications of 4.75 mm, 6 mm, and 8 mm respectively. The significance of using a moisture-proof board for the heel material is that the heel must first be moisture-proof, and at the same time have good physical and mechanical properties to prevent cracking and wear resistance. The significance of using moisture-proof boards for floors is that the boards must be moisture-proof to prevent bending deformation and thickness expansion caused by moisture absorption. At the same time, they have good physical and mechanical properties, which improves the quality of the product.