Engineered veneer

| Product Name | EV veneer,engineered veneer and reconstituted veneer |

|---|---|

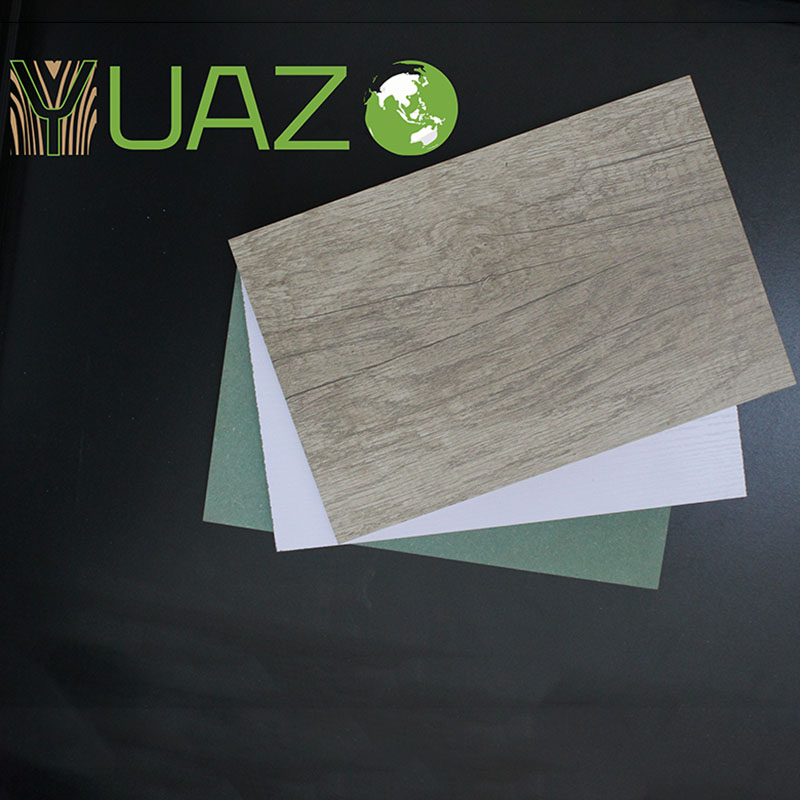

| Size | 4x8, 4x73x7, 4x6, 3x6 or as required |

| Thickness | 0.1-3mm (0.1mm,0.15mm,0.25mm,0.45mm,0.5mm,1.5mm,2.5mm,3mm) |

| Grade | A grade, B grade |

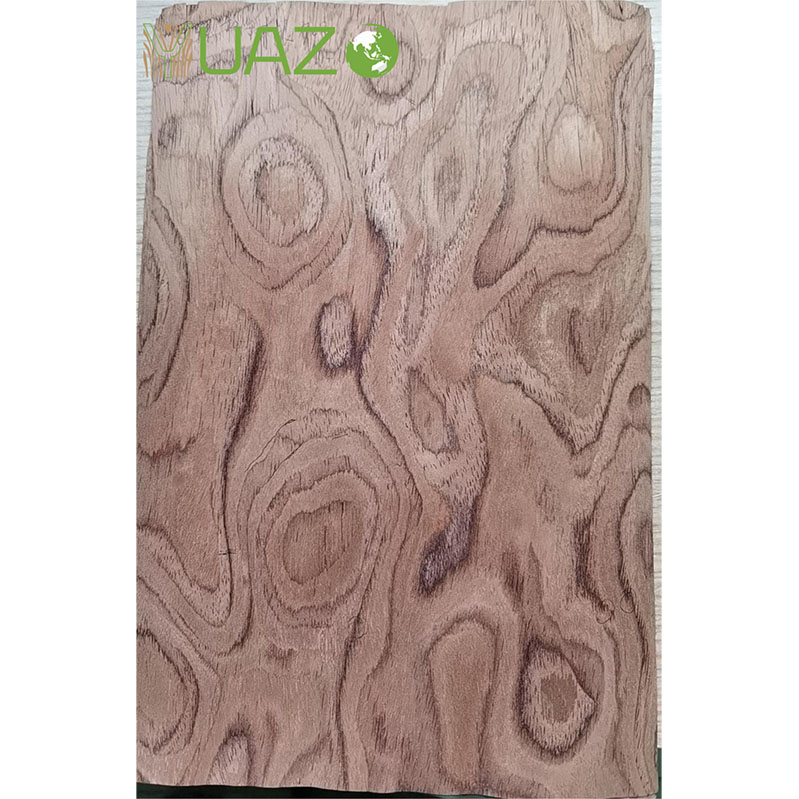

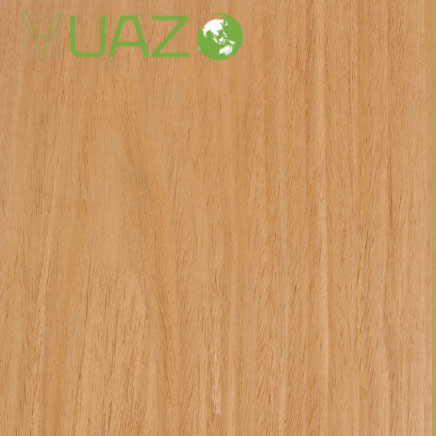

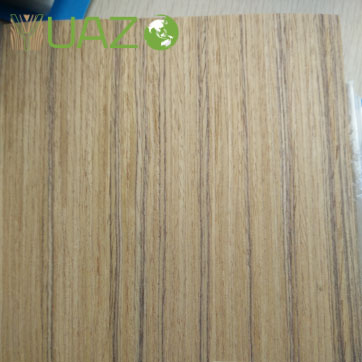

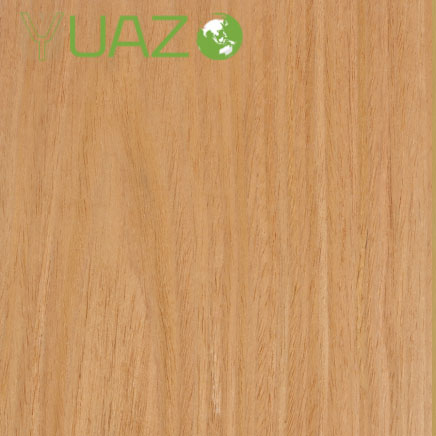

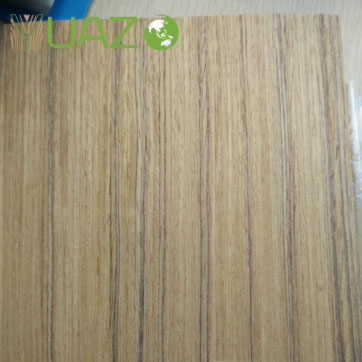

| Veneer species | EV ash veneer,EV oak veneer,EV teak veneer, Recon Gurjan/keruing veneer, EV walnut veneer, recon okoume veneer,recon poplar veneer, recon teak veneer, recon sapele veneer etc. |

| Moisture Content | ≤ 15% |

| Applications | Using as face of plywood,MDF and block board, as core material for manufacturing of plywood and flush doors. |

| Packing | Standard export pallet packing |

| Transport | By break bulk or container |

| Delivery time | Within in 10-15 days after receiving deposit |

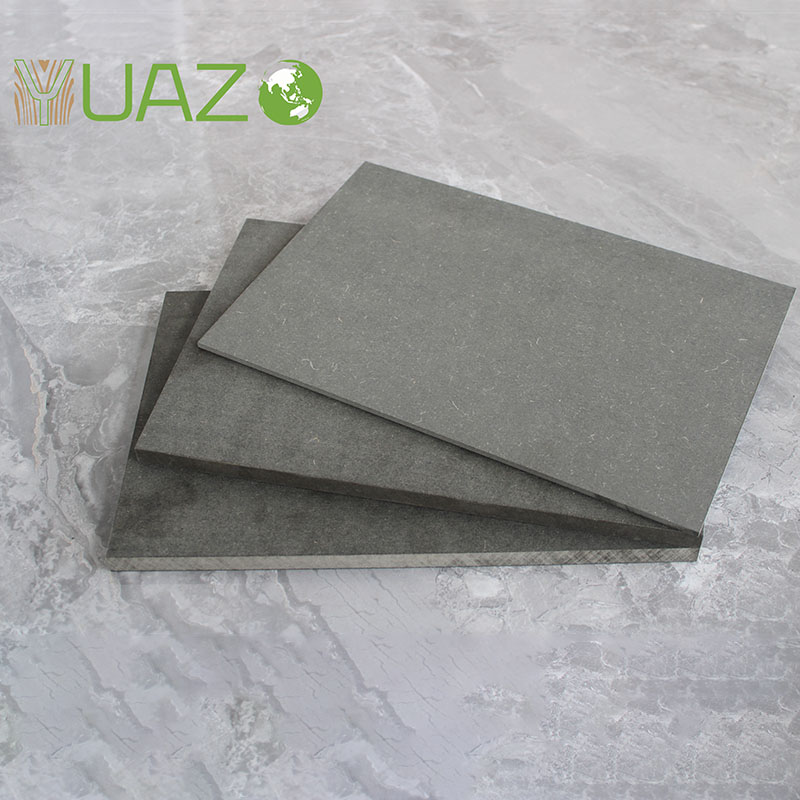

Engineered veneer (EV) - also known as reconstitued veneer (recon) or recomposed veneer (RV) - is a re-manufactured product. Like natural veneer, engineered veneer is real-wood and born from a natural core. The difference is that the veneer is engineered though templates and pre-developed dye moulds.

Compared with natural veneer, the texture and color are richer and more diverse. Not only are the defects of natural veneer such as dead knots, wormholes, and white edges eliminated, the surface is smoother and the color is more consistent. The wood utilization rate is high, it is easy to process, and it can be copied.